Search

How to choose a suitable Inverter for existing motors? There is a certain amount of knowledge and a little skill in this. As a professional electromechanical equipment service provider, Rockss Automation not only helps customers choose motors well, but also cannot make careless choices about motor control. So, let's analyze and analyze today how Siemens Inverters can be perfectly combined with Siemens motors.

SIEMENS 6SE3211-5BA40 Inverter

The commonly used types of Siemens Inverters are as follows: 6SE6440, 430, and 420. Usually, the choice between these three is also meticulous. Here are a few points for everyone from Rockss Automation:

1. Products powered by 380-480VAC and without filters are commonly used in Siemens 440 series Inverters. Just find the corresponding model for the 440 series.

2. There are two types of product oils for partial power consumption: imported with original packaging and domestically produced. The price of domestically produced products is cheaper compared to pure imported products.

3. The power corresponding to the Inverter model refers to the high torque output power.

4. Generally, the standard Siemens Inverter is optional and does not include a control panel. The control panel needs to be ordered separately. The control panel includes both Chinese and English versions. The English control panel is a bit cheaper than the Chinese one.

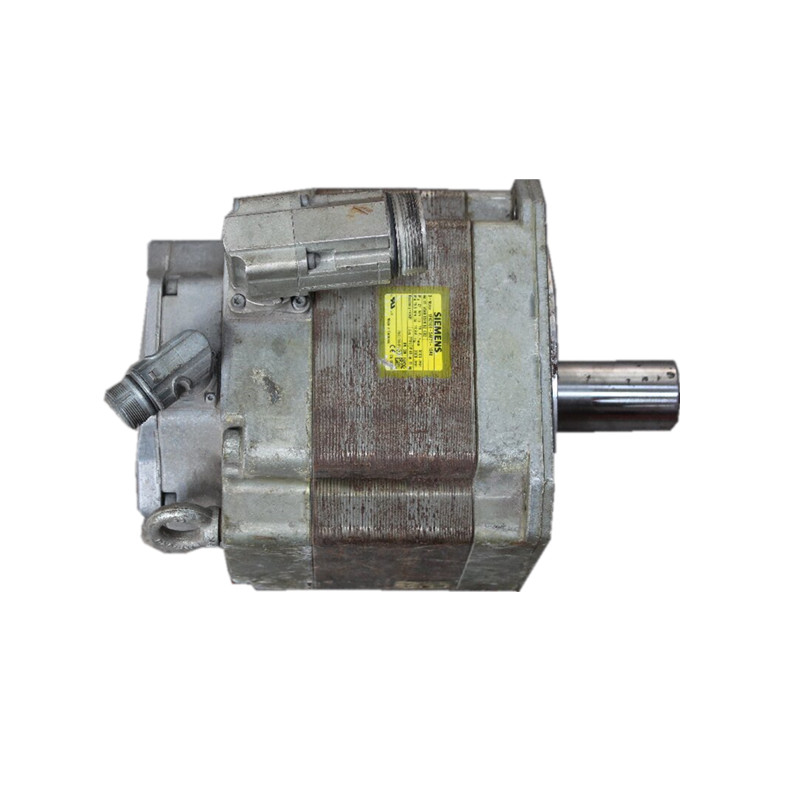

SIEMENS 1FK7101-5AF71-1SA0 Motor

As mentioned above, the 440 series Siemens Inverter commonly used for 380V voltage of domestic standard motors. So, how to choose a suitable 440 series frequency converter? 440 power range: 0.37-255kW. Among them, 0.12kW-200kW (CT constant torque); 0.12kW-250kW (VT variable torque). Generally speaking, the Inverter is matched according to the power of the motor, and the ratio is 1:1 original. If the distance between the heavy load and the Inverter is relatively long, the power of the Inverters one to two levels higher than the power of the motor. If a Inverters equipped with multiple motors, it is sufficient to choose one level higher than the motor power, which is not the total power of the motors carried.

When selecting a Inverter, the following parameters should generally be considered:

1. Power

Choose the high-power Inverter for the high-power motor. However, for special occasions such as high temperatures and altitudes, it can cause a reduction in the capacity of the frequency converter, making it easy for the Inverter to amplify by one gear.

2. Current

The rated current of the Inverter is greater than the maximum current of the motor operation, and it is generally marked on the nameplate.

3. Supply voltage

Generally, low-voltage frequency converters have single-phase 220-240V, three-phase 380-480V power supply, etc. The specific selection is rated according to actual needs.

4. Load inertia

In some situations, such as most ventilation ducts, there is no requirement for the motor to stop in a timely manner, while in some transmission belts, it is required to stop in a timely manner, so it can also be used as a reference condition for selecting frequency converters.

SIEMENS 6SE3210-7BA40 Inverter

A Siemens Inverter can control multiple motors. This application situation is commonly referred to as "one dragging many". It has been running for many years and rarely malfunctions. However, it is important to pay attention to the following points when dragging a frequency converter:

1. The control method must use linear V/F control

2. One drag multiple is only used in situations where there are no strict requirements for motor speed regulation;

3. The total rated current of each motor should be less than the rated current of the variable frequency;

4. Independent thermal relays should be installed on each motor.

5. The power of each motor should be consistent as much as possible

6. The differences in physical characteristics of each output circuit should be minimized, including:

A. Motor characteristics, such as speed;

B. Cable characteristics, such as cross-sectional area, length, and material.

7. If the motor characteristics are basically consistent and the cable length approaches the allowable limit length of the frequency converter, methods such as increasing the outlet reactor, reducing the switching frequency, and appropriately increasing the Inverter can be adopted.

For mid-range applications, customers usually consider Siemens or ABB when choosing frequency converters. Indeed, in certain high-end special industries such as lifting and steel rolling, I personally believe that using frequency converters from foreign brands such as Siemens will provide more protection and fewer malfunctions. It's a lot easier to use in the later stage.